2.5

Results for thermal printer mechanisms

Discover the latest in thermal printer mechanisms and enhance your business with precision and reliability. Whether you're a small retail shop or a large manufacturing facility, thermal printers play a crucial role in your daily operations. Understanding the mechanisms behind these printers can help you make informed decisions and improve your efficiency.

Thermal printer mechanisms operate on a simple yet effective principle. They use heat to transfer color from a thermal paper coating to the paper surface. This technology is not only fast but also energy-efficient, making it ideal for a wide range of applications. From receipt printing in retail stores to labels and tags in manufacturing, thermal printers offer a versatile solution that meets your unique needs.

One of the most significant advantages of thermal printer mechanisms is their durability. Unlike traditional inkjet printers, thermal printers don't use ink cartridges, reducing maintenance and replacement costs. This feature makes them a cost-effective choice, especially in high-volume printing environments. Furthermore, the lack of moving parts in thermal printers ensures they have a long lifespan, contributing to a lower total cost of ownership.

Thermal printer mechanisms come in various forms, including thermal transfer, direct thermal, and thermal ribbon. Each type has its own set of advantages and is suitable for different applications. Direct thermal printers are ideal for producing clear and permanent images on thermal paper, making them perfect for receipts and invoices. On the other hand, thermal transfer printers use a wax or resin ribbon, allowing for higher-quality and more durable prints, which are ideal for labels and signage.

Incorporating thermal printer mechanisms into your business can streamline your workflow and improve customer satisfaction. For instance, in retail settings, quick and accurate receipt printing enhances the customer experience. In manufacturing, the ability to print high-quality labels and tags ensures that products are easily traceable and compliant with industry standards.

Choosing the right thermal printer mechanism for your business is crucial. Factors such as print quality, print speed, paper type, and environmental conditions should all be considered. For example, if you operate in a high-temperature environment, you'll need to select a thermal printer that can withstand extreme conditions without compromising on print quality.

In addition to the printers themselves, understanding the maintenance and cleaning procedures for thermal printer mechanisms is essential. Regular cleaning and maintenance can significantly extend the life of your printer and ensure it operates efficiently. Most thermal printers come with user manuals that provide detailed instructions on how to perform these tasks effectively.

Thermal printer mechanisms are not just about functionality; they also offer a sustainable solution for businesses. By reducing the use of ink and minimizing waste, these printers contribute to a greener and more environmentally friendly operation. If sustainability is a priority for your business, thermal printers are an excellent choice.

In conclusion, thermal printer mechanisms are the backbone of many business operations. From retail to manufacturing, these printers provide a reliable and efficient solution for your printing needs. By understanding the mechanisms and making the right choices, you can enhance your business processes and achieve greater success. Whether you're a small business owner or a large corporation, investing in the right thermal printer mechanisms is a smart move that pays off in the long run.

High-Quality Thermal Printer Mechanism - Fast Printing, Durable & Easy Setup - Perfect For Business!

In today’s fast-paced world, businesses and organizations are constantly on the lookout for efficient and reliable solutions to meet their printing needs. Thermal printer mechanisms have become a cornerstone in this digital revolution, offering businesses a wide range of advantages over traditional printers. These innovative devices use a unique thermal transfer process to print images, text, and barcodes directly onto thermal paper. The result is high-quality, long-lasting prints that can withstand various conditions, making thermal printers a favorite among retail, healthcare, and industrial sectors.

Understanding the Basics of Thermal Printer Mechanisms

At its core, a thermal printer mechanism works by applying heat to thermal paper to produce an image. Unlike inkjet or laser printers, thermal printers don’t use any liquids, toners, or other consumables. Instead, they rely on precise heating elements that activate the dye within the thermal paper. The heat triggers a chemical reaction, causing the dye to change color and produce the desired print. This process is swift, clean, and cost-effective, making thermal printers a popular choice for environments where efficiency and reliability are crucial.

The Role of Thermal Printer Mechanisms in Different Industries

Thermal printer mechanisms play a pivotal role in various industries, offering tailored solutions to meet specific needs. In retail, for instance, thermal printers are used extensively for point-of-sale (POS) systems. They quickly generate receipts and loyalty cards, enhancing customer satisfaction and streamlining checkout processes. The thermal printer mechanisms in these devices are designed to withstand frequent usage and harsh environments, ensuring that customers receive clear and accurate receipts.

In healthcare, thermal printers are indispensable for generating patient records, lab reports, and medical forms. The high-quality prints produced by thermal printer mechanisms are critical for maintaining accurate medical records and ensuring that healthcare providers can access patient information quickly and efficiently. Additionally, thermal printers are ideal for hospitals where clean, reliable printing is essential for patient safety and compliance with regulatory standards.

In the industrial sector, thermal printers are used for labeling, inventory management, and quality control. The robust thermal printer mechanisms in these devices can handle tough industrial environments, producing durable labels that can withstand extreme temperatures, chemicals, and mechanical stress. This makes them perfect for manufacturing, warehousing, and logistics operations.

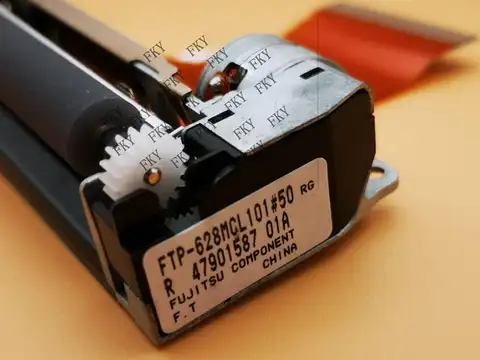

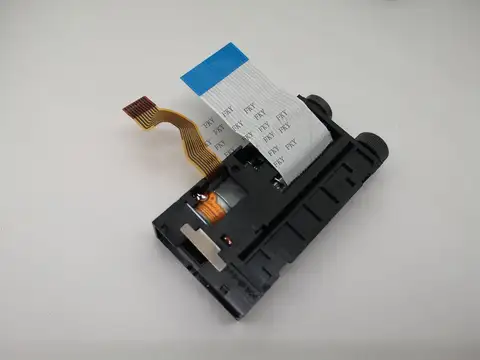

Key Components of Thermal Printer Mechanisms

To understand how thermal printers function, it’s essential to familiarize yourself with their key components. These mechanisms typically consist of:

1. Heating Elements: These are the core components that generate the heat required to produce the print. Modern thermal printers use advanced heating elements that can quickly and accurately apply the right amount of heat.

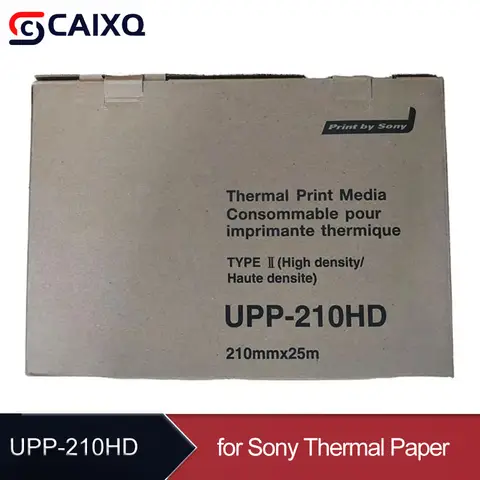

2. Thermal Paper: This specialized paper contains a layer of heat-sensitive dye. When heat is applied, the dye changes color, creating the print. Thermal paper comes in various grades, with different levels of heat sensitivity and print quality.

3. Fuser and Drive Mechanism: These components control the movement of the thermal paper and the thermal print head. The fuser ensures that the print head comes into contact with the paper at the correct speed and pressure, while the drive mechanism manages the paper feed.

4. Controller Board: This component manages the thermal printer mechanisms, controlling the heating elements and ensuring that the print process is carried out accurately and efficiently.

Advantages of Thermal Printer Mechanisms

Thermal printer mechanisms offer numerous advantages that make them a preferred choice for businesses of all sizes. Here are some of the key benefits:

1. Cost-Effective: Unlike inkjet or laser printers, thermal printers don’t require ink or toner. This reduces operational costs and eliminates the need for regular cartridge replacements.

2. Durability: The absence of moving parts and the use of thermal paper make thermal printers highly durable. They can withstand frequent usage and harsh conditions, ensuring consistent performance over time.

3. Speed and Efficiency: Thermal printers produce prints quickly and efficiently, which is particularly beneficial in high-volume environments. The rapid print process ensures that businesses can meet customer demands without delay.

4. Customization: Many thermal printers offer customization options, allowing users to adjust settings such as print quality, print speed, and paper type to meet specific needs.

5. Environmentally Friendly: The use of thermal paper and the absence of ink or toner make thermal printers more environmentally friendly. They produce less waste and have a lower carbon footprint compared to traditional printers.

Choosing the Right Thermal Printer Mechanism for Your Needs

When selecting a thermal printer mechanism, it’s crucial to consider your specific requirements and the environment in which the printer will be used. Here are some factors to consider:

1. Print Quality: Ensure that the thermal printer mechanism can produce high-quality prints that meet your standards. Look for printers that offer adjustable print settings and high-resolution prints.

2. Compatibility: Check if the printer is compatible with your existing systems and software. Many modern thermal printers offer connectivity options such as USB, Ethernet, and Wi-Fi, making them easy to integrate into existing workflows.

3. Durability: Choose a printer with robust thermal printer mechanisms that can withstand frequent usage and harsh conditions. Look for printers with durable build quality and reliable components.

4. Warranty and Support: Consider the manufacturer’s warranty and support services. A reliable warranty and responsive support can save you time and money in the long run.

Maintenance and Care of Thermal Printer Mechanisms

Proper maintenance and care are essential for extending the life of your thermal printer mechanisms. Here are some tips to help you maintain your thermal printers:

1. Regular Cleaning: Clean the thermal print head and the fuser regularly to prevent dust and debris from affecting print quality. Use a soft cloth or brush to gently remove any accumulated particles.

2. Handle with Care: Handle the thermal paper carefully to avoid damage. Store it in a dry, cool place to prevent any changes in the paper’s condition.

3. Calibration Checks: Periodically check the calibration of the thermal printer mechanisms. This ensures that the heating elements are functioning correctly and that prints are accurate.

4. Software Updates: Keep your thermal printer software up to date to ensure that you have access to the latest features and improvements.

Conclusion: Embrace the Power of Thermal Printer Mechanisms

Thermal printer mechanisms have revolutionized the way businesses print, offering unparalleled efficiency, reliability, and cost-effectiveness. Whether you’re in retail, healthcare, or industry, the benefits of thermal printers are clear. By choosing the right thermal printer mechanism, you can streamline your operations, improve print quality, and reduce operational costs.

At [Your Company Name], we understand the importance of thermal printer mechanisms in today’s digital landscape. We offer a wide range of thermal printers that cater to diverse needs, ensuring that you find the perfect solution for your business. Whether you need a reliable POS system, a high-quality healthcare printer, or an industrial labeling solution, our thermal printer mechanisms will exceed your expectations.

Contact us today to learn more about our thermal printer mechanisms and how they can enhance your business operations. Join the millions of satisfied customers who have already embraced the power of thermal printing.

Explore the Power of Thermal Printer Mechanisms with [Your Company Name]

Contact Us

[Your Company Name]

Address: [Your Address]

Phone: [Your Phone Number]

Email: [Your Email]

Website: [Your Website URL]

[Your Company Name] - Where Precision Meets Reliability.