Búsquedas relacionadas

4.5

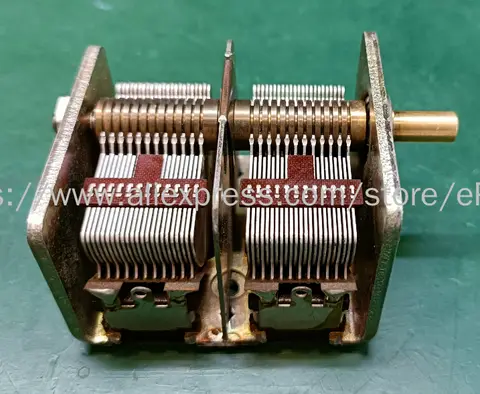

Resultados para variable capacitor

La precisión en ingeniería electrónica es vital para lograr rendimientos óptimos y eficiencia en el diseño de dispositivos. Cuando hablamos de componentes esenciales para esta precisión, la variable capacitor es uno de los primeros en mencionarse. Los variable capacitor son cruciales para el funcionamiento de una amplia gama de aplicaciones, desde circuitos de radio hasta sistemas de audio profesional.

En nuestro catálogo, encontrarás una variedad de variable capacitor de alta calidad que pueden adaptarse a diferentes necesidades técnicas. Nuestros variable capacitor están diseñados para ofrecer una resistencia al desgaste superior y una gran estabilidad, lo que significa que se mantendrán precisos durante largos períodos de uso.

Si estás buscando mejorar la calidad de tu diseño, o si necesitas ajustar la frecuencia de tu circuito, nuestras variable capacitor son la solución perfecta. Ofrecemos opciones de diferentes valores de capacitancia, lo que permite una personalización total según tus requisitos específicos.

Para aquellos que necesitan un alto grado de ajustabilidad, nuestros variable capacitor son ideales. Pueden ser regulados en tiempo real para garantizar que se ajusten perfectamente a cualquier escenario de uso. Además, son perfectos para pruebas y desarrollo, permitiendo realizar ajustes precisos y constantes.

Además, nuestros variable capacitor son resistentes a altas temperaturas y pueden soportar tensiones extremas, lo que los convierte en un excelente complemento para aplicaciones industriales y de alto rendimiento.

En cuanto a la eficiencia energética, los variable capacitor contribuyen significativamente al consumo de energía en un dispositivo. Al poder ajustar la frecuencia y el comportamiento del circuito, puedes garantizar que tu diseño funcione de manera óptima y eficiente, lo que a su vez reduce el gasto energético.

Si buscas un proveedor confiable y con experiencia, estás en el lugar correcto. Ofrecemos soporte técnico continuo y asesoramiento experto para ayudarte a elegir el variable capacitor que mejor se adapte a tus necesidades. Además, garantizamos que todos nuestros componentes cumplen con los más altos estándares de calidad y confiabilidad.

No esperes más para mejorar la precisión y la eficiencia de tus diseños electrónicos. Consulta nuestra amplia gama de variable capacitor y descubre cómo podemos ayudarte a lograr los resultados que buscas. Con nuestra ayuda, tus proyectos se convertirán en éxito seguro.

Cárter Capacitor Variable 10Pf-330Pf Para Radio Hf Tuning 5Uipe Piezas Repuesto Envío Rápido!

Los capacitorios variables son componentes esenciales en el diseño de diversos sistemas electrónicos y son fundamentales para las aplicaciones donde la regulación del voltaje o la frecuencia es crucial. Estos dispositivos pueden ajustarse para variar el valor de la capacitancia, permitiendo un control preciso del comportamiento eléctrico de un circuito.

Cómo Funcionan los Capacitores Variables

Los capacitores variables son de un tipo de capacitor que puede ajustar su capacidad de almacenamiento de electricidad. Esto se logra mediante la modificación de la distancia entre las placas o el área de superficie que se contraponen. La capacitancia en un capacitor variable se expresa con la fórmula \(C = \frac{\varepsilon A}{d}\), donde \(C\) es la capacitancia, \(\varepsilon\) es la permitividad del material entre las placas, \(A\) es la superficie de las placas y \(d\) es la distancia entre ellas. La capacidad de ajuste de estos dispositivos es de gran utilidad en diversas aplicaciones.

Uso en Circuito RF

Los capacitores variables son indispensables en circuitos de frecuencia de radio (RF). Ajustan la frecuencia resonante del circuito, lo que facilita la selección y modulación de señales en comunicaciones inalámbricas y equipos de audio. Estos componentes permiten ajustar la banda de frecuencia deseada, mejorando la calidad y la eficiencia del sistema.

Implementación en Circuitos de Amplificación

En circuitos de amplificación, los capacitores variables se utilizan para ajustar la tensión de entrada y salida. Permiten controlar la respuesta en frecuencia y la línea de carga del circuito. La capacidad de ajustar el voltaje a través de estos componentes es esencial para obtener un rendimiento óptimo y la estabilidad necesaria.

Ajuste de Frecuencia en Circuito de Resonancia

Los capacitores variables son fundamentales en circuitos de resonancia. Al ajustar la capacitancia, se puede controlar la frecuencia resonante del circuito, lo que es crucial en aplicaciones como resonadores de radio y circuitos de control de frecuencia en relojes electrónicos.

Regulación de Voltaje en Baterías

En sistemas de energía, los capacitores variables juegan un papel vital en la regulación del voltaje. Pueden ajustarse para mantener un voltaje constante en condiciones cambiantes, lo que es esencial para la estabilidad y el rendimiento de equipos electrónicos. Su capacidad de almacenar energía de corto plazo permite un flujo continuo de potencia y la estabilización de tensiones fluctuantes.

Uso en Diseño de Circuito de Televisión

En sistemas de televisión, los capacitores variables se utilizan para ajustar la frecuencia de la antena y la señal de video. Su capacidad de controlar la impedancia y la resonancia es esencial para el funcionamiento óptimo de la televisión y el rendimiento de la recepción de señales.

Implementación en Circuito de Conmutación

En circuitos de conmutación, los capacitores variables se utilizan para controlar la transición de corriente entre diferentes estados. La modulación del voltaje y la impedancia permiten la optimización de la velocidad de conmutación y la estabilidad del sistema.

Aplicaciones en Sistemas de Audio

En sistemas de audio, los capacitores variables se utilizan para ajustar la tonalidad y la respuesta en frecuencia. La capacidad de modificar el voltaje y la impedancia es esencial para la equalización y la optimización del sonido.

Implementación en Diseño de Circuito de Comunicaciones Satelitales

En circuitos de comunicaciones satelitales, los capacitores variables se utilizan para ajustar la resonancia del circuito y la impedancia. Su capacidad para controlar la frecuencia de resonancia y la estabilidad del sistema es crucial para la transmisión de señales de alta calidad en comunicaciones satelitales.

Uso en Diseño de Circuito de Radar

En circuitos de radar, los capacitores variables se utilizan para ajustar la frecuencia de resonancia y la velocidad de conmutación. La capacidad de controlar la impedancia y la resonancia es esencial para la detección y el rastreo de objetivos.

Implementación en Diseño de Circuito de Iluminación LED

En sistemas de iluminación LED, los capacitores variables se utilizan para controlar la tensión de alimentación y la frecuencia de conmutación. Su capacidad para ajustar la impedancia y la resonancia permite una mayor eficiencia energética y una mejor calidad de iluminación.

Aplicaciones en Sistemas de Control de Motor

En sistemas de control de motor, los capacitores variables se utilizan para ajustar la impedancia y la tensión en el circuito de alimentación. La capacidad de controlar la resonancia y la estabilidad del sistema es crucial para el funcionamiento óptimo del motor.

Implementación en Diseño de Circuito de Televisión

En sistemas de televisión, los capacitores variables se utilizan para ajustar la frecuencia de la antena y la señal de video. Su capacidad para controlar la impedancia y la resonancia es esencial para el funcionamiento óptimo de la televisión y el rendimiento de la recepción de señales.

Aplicaciones en Diseño de Circuito de Receptor de Radio

En circuitos de receptor de radio, los capacitores variables se utilizan para ajustar la resonancia del circuito y la impedancia. La capacidad para controlar la frecuencia de resonancia y la estabilidad del sistema es crucial para la detección y el rastreo de señales de radio.

Implementación en Diseño de Circuito de Amplificador de Sonido

En circuitos de amplificador de sonido, los capacitores variables se utilizan para ajustar la respuesta en frecuencia y la impedancia. Su capacidad para controlar la resonancia y la estabilidad del sistema es crucial para la calidad del sonido y la potencia de salida.

Aplicaciones en Diseño de Circuito de Transmisor de Radio

En circuitos de transmisor de radio, los capacitores variables se utilizan para ajustar la resonancia del circuito y la impedancia. La capacidad para controlar la frecuencia de resonancia y la estabilidad del sistema es crucial para la transmisión de señales de radio de alta calidad.

Implementación en Diseño de Circuito de Amplificador de Audio

En circuitos de amplificador de audio, los capacitores variables se utilizan para ajustar la respuesta en frecuencia y la impedancia. Su capacidad para controlar la resonancia y la estabilidad del sistema es crucial para la calidad del sonido y la potencia de salida.

Aplicaciones en Diseño de Circuito de Radar

En circuitos de radar, los capacitores variables se utilizan para ajustar la resonancia del circuito y la impedancia. La capacidad para controlar la frecuencia de resonancia y la estabilidad del sistema es crucial para la detección y el rastreo de objetivos.

Implementación en Diseño de Circuito de Comunicaciones Satelitales

En circuitos de comunicaciones satelitales, los capacitores variables se utilizan para ajustar la resonancia del circuito y la impedancia. La capacidad para controlar la frecuencia de resonancia y la estabilidad del sistema es crucial para la transmisión de señales de alta calidad en comunicaciones satelitales.

Aplicaciones en Diseño de Circuito de Antena

En sistemas de antena, los capacitores variables se utilizan para ajustar la resonancia del circuito y la impedancia. La capacidad para controlar la frecuencia de resonancia y la estabilidad del sistema es crucial para la recepción y transmisión de señales.

Implementación en Diseño de Circuito de Control de Motor

En sistemas de control de motor, los capacitores variables se utilizan para ajustar la resonancia del circuito y la impedancia. La capacidad para controlar la frecuencia de resonancia y la estabilidad del sistema es crucial para el funcionamiento óptimo del motor.

Aplicaciones en Diseño de Circuito de Control de Potencia

En circuitos de control de potencia, los capacitores variables se utilizan para ajustar la resonancia del circuito y la impedancia. La capacidad para controlar la frecuencia de resonancia y la estabilidad del sistema es crucial para el rendimiento óptimo del sistema.

Implementación en Diseño de Circuito de Regulación de Voltaje

En circuitos de regulación de voltaje, los capacitores variables se utilizan para ajustar la resonancia del circuito y la impedancia. La capacidad para controlar la frecuencia de resonancia y la estabilidad del sistema es crucial para la estabilidad del voltaje.

Aplicaciones en Diseño de Circuito de Iluminación LED

En sistemas de iluminación LED, los capacitores variables se utilizan para ajustar la resonancia del circuito y la impedancia. La capacidad para controlar la frecuencia de resonancia y la estabilidad del sistema es crucial para la eficiencia energética y la calidad de la iluminación.

Implementación en Diseño de Circuito de Comunicaciones Satelitales

En circuitos de comunicaciones satelitales, los capacitores variables se utilizan para ajustar la resonancia del circuito y la impedancia. La capacidad para controlar la frecuencia de resonancia y la estabilidad del sistema es crucial para la transmisión de señales de alta calidad en comunicaciones satelitales.

Aplicaciones en Diseño de Circuito de Televisión

En sistemas de televisión, los capacitores variables se utilizan para ajustar la resonancia del circuito y la impedancia. La capacidad para controlar la frecuencia de resonancia y la estabilidad del sistema es crucial para el funcionamiento óptimo de la televisión.

Implementación en Diseño de Circuito de Recepción de Señales

En circuitos de recepción de señales, los capacitores variables se utilizan para ajustar la resonancia del circuito y la impedancia. La capacidad para controlar la frecuencia de resonancia y la estabilidad del sistema es crucial para la detección y el rastreo de señales.

Conclusión

Los capacitores variables son componentes esenciales en diversos sistemas electrónicos, ofreciendo una gama amplia de aplicaciones. Su capacidad para ajustar la capacitancia permite una gran flexibilidad y control en el diseño y operación de circuitos. La elección de un capacitador variable adecuado para una aplicación específica puede mejorar significativamente el rendimiento y la eficiencia del sistema.

See more details about variable capacitor in AliExpress Video Page.